Management Application of RFID Washable Tags on Uniforms

1. Application of RFID laundry tags

At present, places such as hotels, playgrounds, large factories, hospitals, etc. have a large number of uniforms to be processed every morning. Employees need to line up in the clothing room to get uniforms, just like shopping in a supermarket and checking out, they need to register and collect them one by one. Afterwards, they have to be registered and returned one by one. Sometimes there are dozens of people in line, and it takes several minutes for each person. Moreover, the current management of uniforms basically adopts the method of manual registration, which is not only very inefficient, but also often leads to mistakes and loss.

The uniforms sent to the laundry factory every day need to be handed over to the laundry factory. The employees in the uniform management office hand over the dirty uniforms to the laundry factory employees. When the laundry factory returns the clean uniforms, the employees of the laundry factory and the uniform management office need to check the type and quantity of the clean uniforms one by one, and sign after the verification is correct. Every 300 pieces of uniforms need about 1 hour of handover time per day. During the handover process, it is impossible to check the quality of laundry, and it is impossible to talk about scientific and modern uniform management such as how to improve the quality of laundry to increase the life of uniforms and how to effectively reduce inventory.

Especially as people’s awareness of disease prevention and treatment continues to increase, it is a very difficult task to count the number of sick clothes when they are handed over.

For high-end hotels, hospitals and other units with high hygiene requirements, employees need to change and wash their work clothes regularly. For employees who do not change and wash regularly, they need to be urged. The current manual management method cannot monitor whether employees change and wash regularly, let alone scientifically based on the attendance of employees. Dynamically adjust the changing frequency of employee uniforms.

The cases of using uniforms to commit crimes are also increasing. How to ensure that the uniforms of the unit will not be used by people with bad intentions has become a very important issue for many enterprises and institutions.

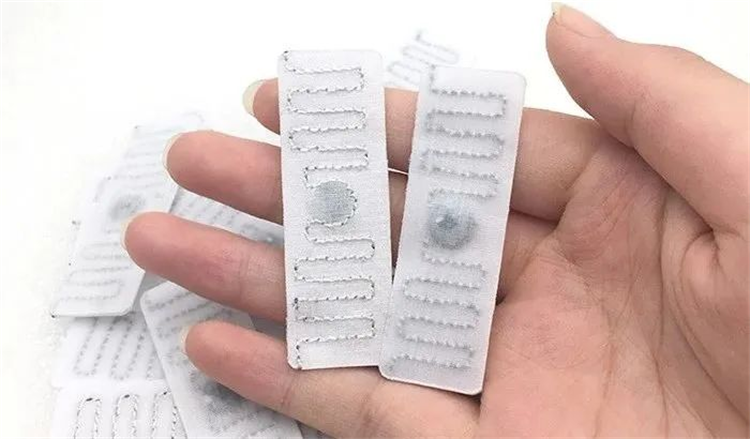

Based on this, a water-resistant, heat-resistant, pressure-resistant, and alkali-resistant RFID washable electronic tag came into being. This tag allows RFID technology to be applied to the management of uniforms.

UHF electronic tags have been widely used in various industries due to their characteristics that they can be read in large quantities at one time over a long distance. Ordinary electronic tags are composed of electronic circuits, so they are easy to fold and not waterproof, which hinders their promotion and application in the field of uniform management. However, the RFID water-resistant label breaks this limitation. In addition, the reusable feature of the label greatly improves its cost performance, which makes the average cost per use of the label very low. At present, many hotels, hospitals, and amusement parks in the world have adopted this label to manage their uniforms, which not only effectively improves the efficiency of uniform management, but also greatly reduces the labor cost of uniform management. At home and abroad, the label has been widely used in hospital gowns and hospital bed sheets and quilt management systems.

2. Detailed description of RFID laundry tags

RFID washable label is the application of RFID radio frequency identification technology. By sewing a strip-shaped electronic washing label on each piece of linen, this rfid electronic label has a globally unique identification code, which can be used repeatedly. It can be used throughout the linen, In the washing management, the UHF RFID reader is used to read in batches, and the usage status and washing times of the linen are automatically recorded. It makes the handover of washing tasks simple and transparent, and reduces business disputes. At the same time, by tracking the number of washings, it can estimate the service life of the current linen for the user and provide forecast data for the procurement plan.

With the development of RFID technology, the application of RFID laundry tags in hotels, playgrounds, large factories, hospitals and other places is becoming more and more popular, which not only improves the efficiency of uniform management, but also ensures the safety and accuracy of data.